General

Thermocouples are sensors for measuring temperature. The main components of thermocouples are a thermocouple, which generates the so-called thermoelectric voltage, and a connection part, such as a plug. Thermocouples are used in many areas of temperature measurement. They are characterized by a high degree of design flexibility and a fast response.

Overview of thermocouples

The following thermocouples are defined in ISO EN 60584-1:

| Typ | Positive wire [plus] |

Negative wire [minus] |

Color DIN [plus / minus] |

Temperature range [°C] |

|---|---|---|---|---|

| J | CuNi | Fe | black / white | -200 +750 |

| K | NiCr | NiAl | green / white | -200 +1100 |

| N | NiCrSi | NiSi | pink / white | -200 +1200 |

| S | PtRh10% | Pt | orange / white | 0 +1600 |

| R | PtRh13% | Pt | orange / white | 0 +1600 |

| B | PtRh30% | PtRh6% | grey / white | +600 +1700 |

| C | WRe25% | WRe5% | red / white | 0 +2200 |

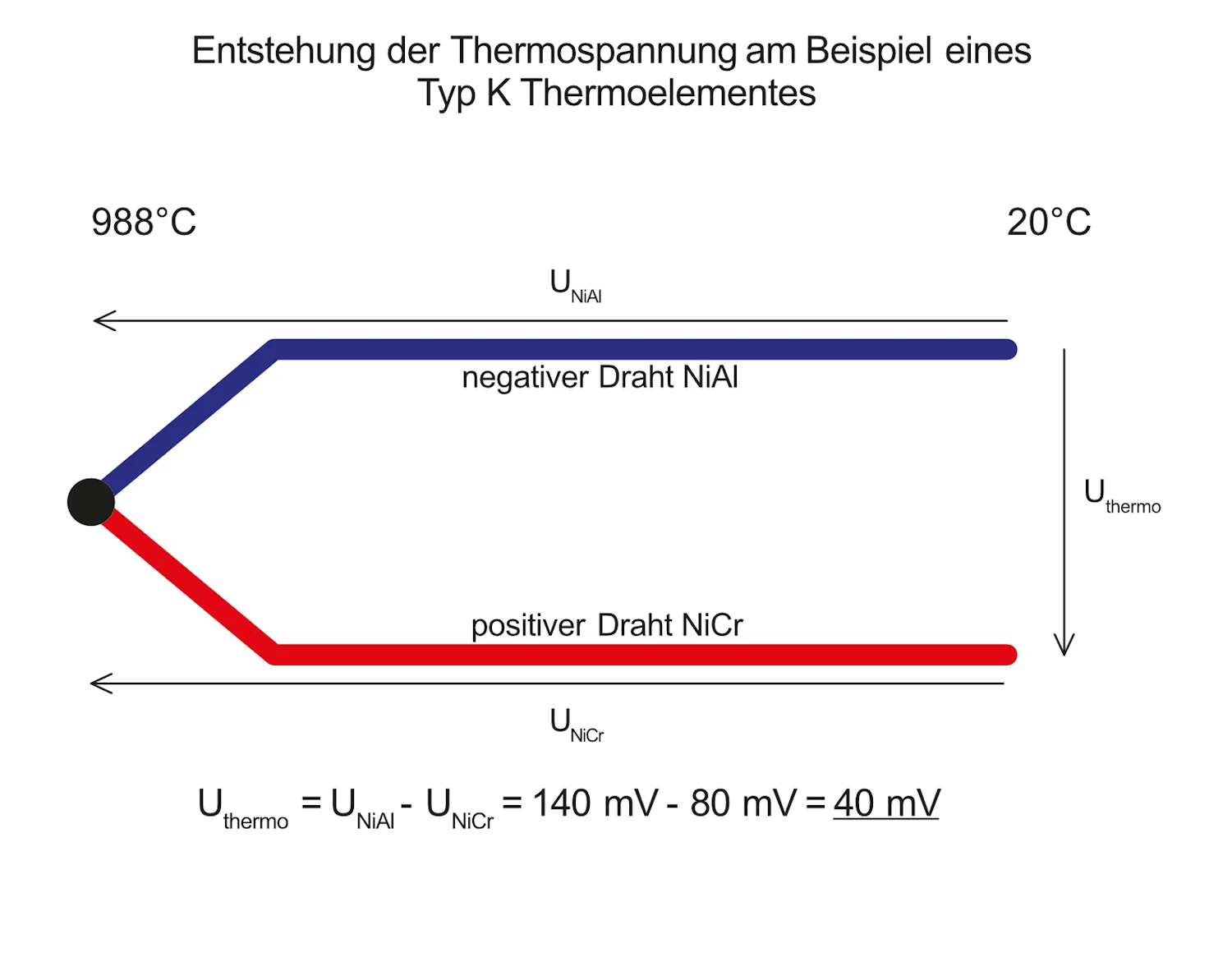

Various combinations of metals/alloys have proven to be advantageous because they have an almost linear voltage curve with temperature.

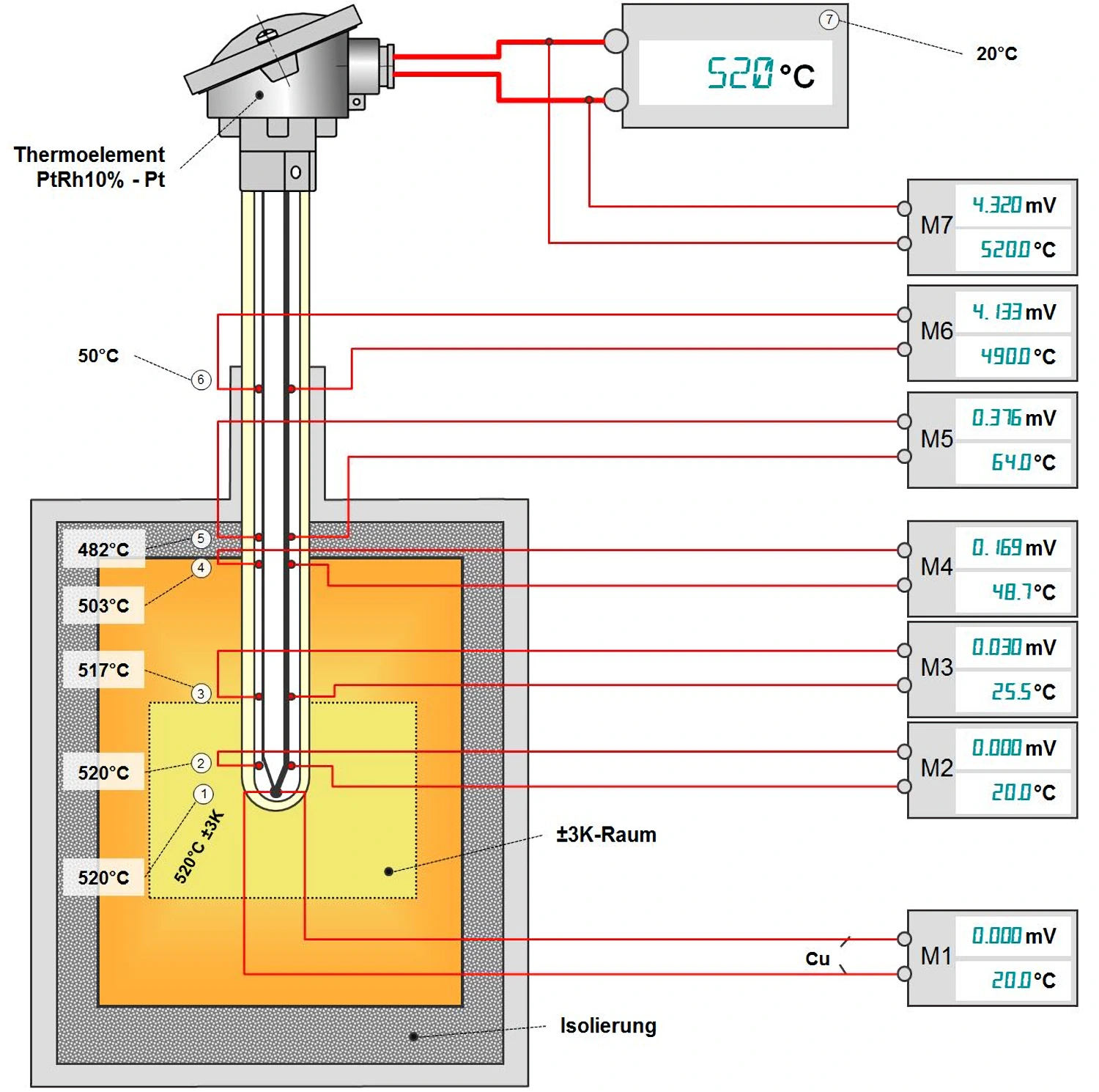

It is important to know that the thermoelectric voltage does not occur at the peak. The voltage occurs between the two wires. Most of the voltage occurs in the area of the greatest temperature difference, for example in the transition from the furnace chamber to the insulation.